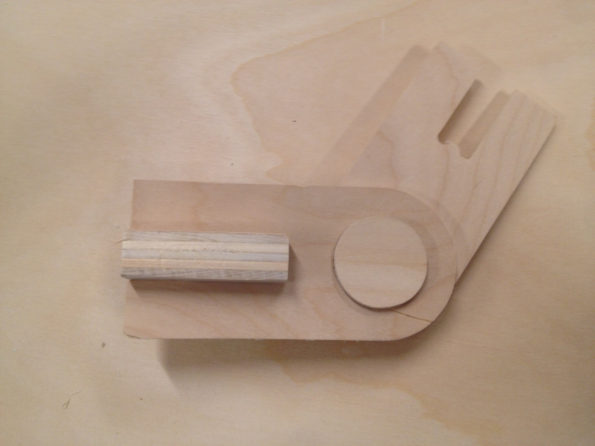

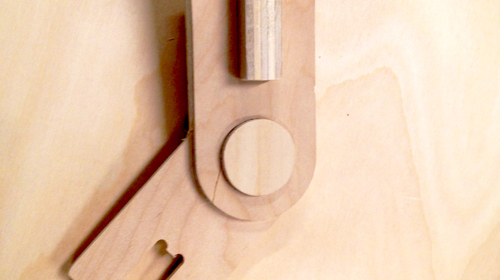

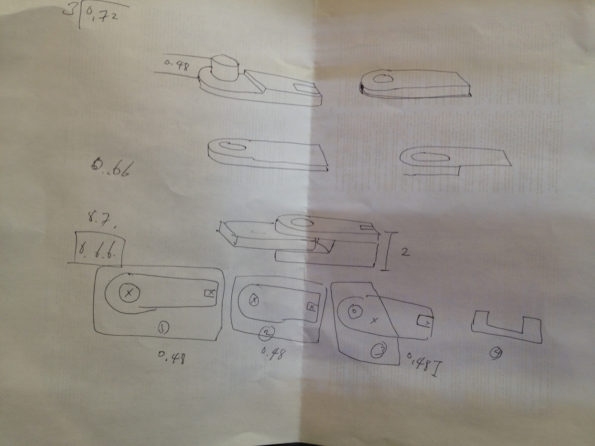

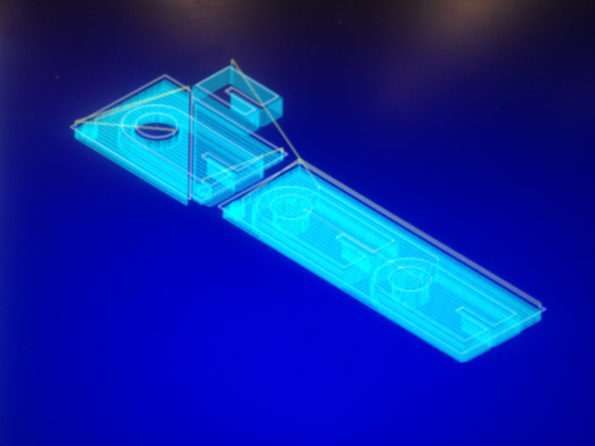

I wanted to make a joinery that can change its movement. I was thinking what if I could use it to a chair or a recliner. So I designed the circle as the point of the movement and designed in a way that I can make by contouring and pocketing.

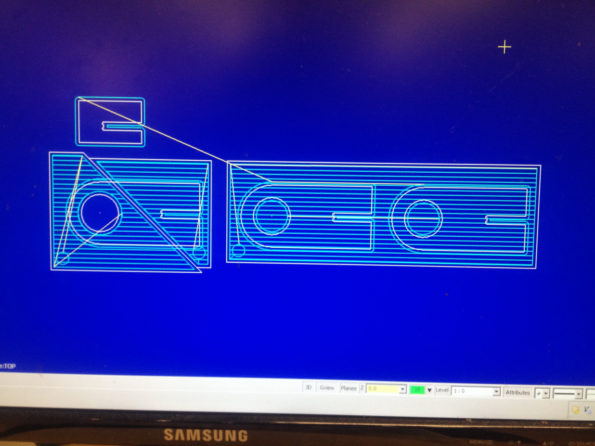

After that, I managed the process at the Mastercam. At the Autocad I used different colors to manage the pocketing and the contouring and I noticed the yellow is not readable at the Mastercam because selection made in the Mastercam is yellow.

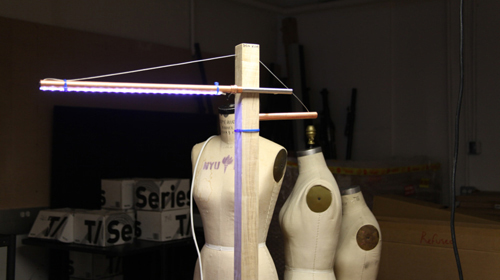

After generating the G-code, I brought the file into the CNC and it was cutting well.

Conclusion. I noticed that in terms of height, there is a lot of difference between the number that I plugged in with the actual size because the pocketing was a cutting, basically tearing off the board a lot.