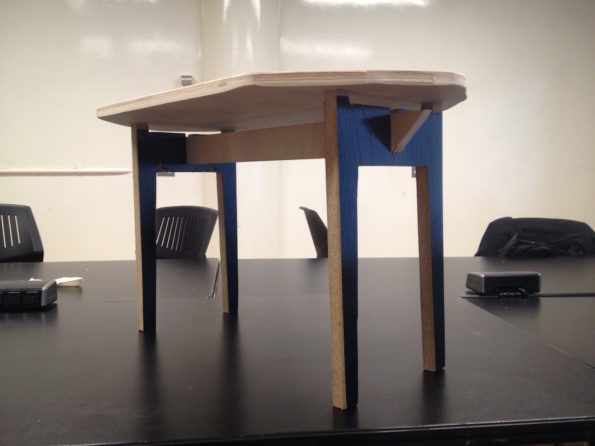

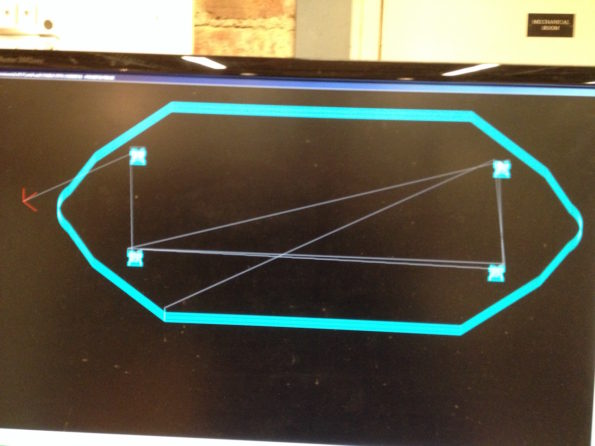

I started with a chair at the Autocad and later changed to the table. I named it as the Doberman Table because the black legs of the table remind me of the Doberman breed canine.

In terms of an assembly, I made pockets bit smaller which is better than bigger. Getting all 4 pieces into the 4 holes was painful. I sanded them and it was now loose by hair. It was fit but easy to remove too. So I glued the top 4 pockets. Here is the result.

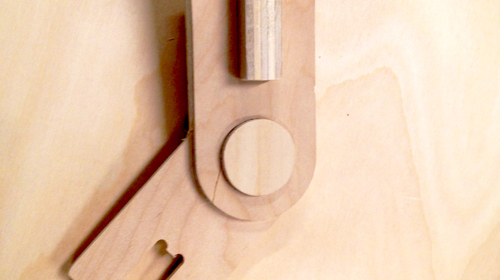

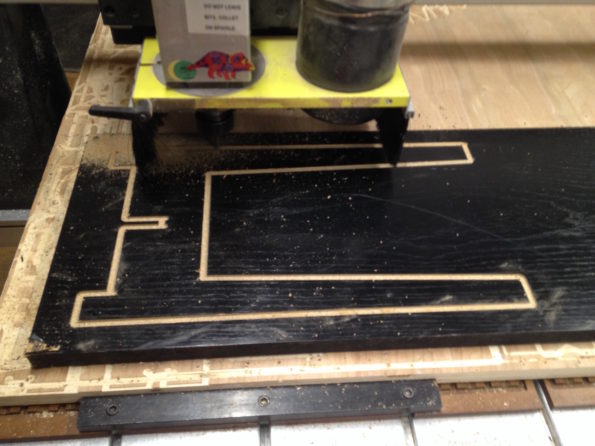

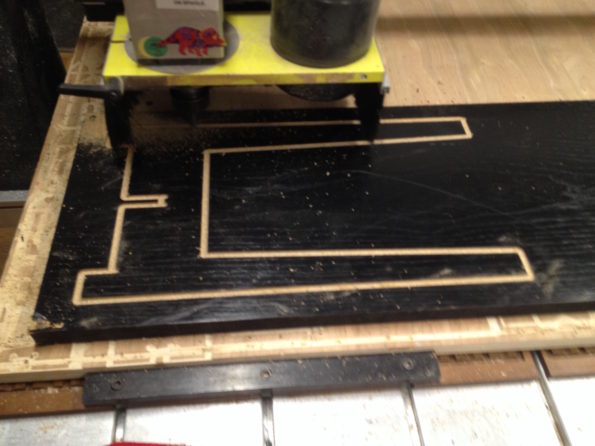

The pieces came out nicely except the black laminated piece was painful to get it out. The laminated was not cut clean I had to cut manually. After Cutting manually, I sanded the edges which torn off some of the laminates. So the parts which got torn off are placed at the inside of the table.

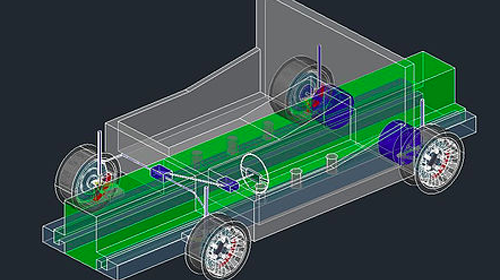

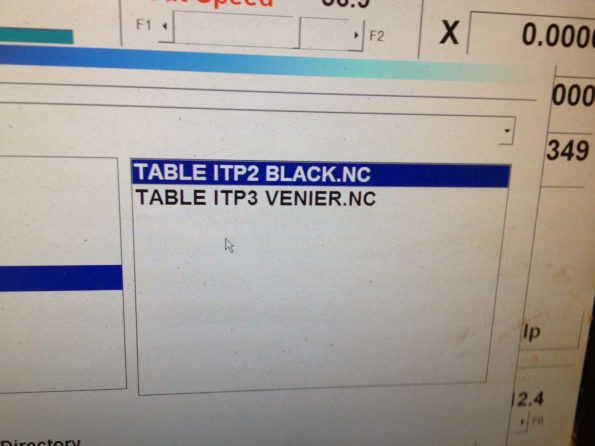

At the master cam, I made three different G code because I had three different pieces of woods. Having multiple woods created multiple G codes. However at the CNC, it was much easier because I basically set the woods all together at the bed of the CNC. As CNC finishes one job, I switched the XYZ zeros to the new board and started cutting with the different files.

Here you may see the black wood is aligned next to the second piece.